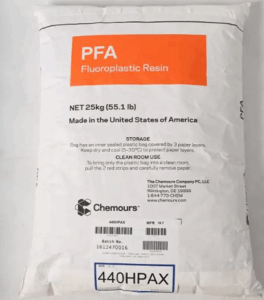

产品说明:

For inventory control purposes product name may be followed by an X.

Products labeled PFA 345 and PFA 345 X are equivalent and all information in this document is applicable to both.

Typical Application

Applications for DuPont™ Teflon ® PFA 345 include extruded tubing, wire and cable insulation, injection molded parts, and chemically resistant linings for bellows, valves, fittings, pipes, pumps, and other fluid-handling components.

Description

DuPont™ Teflon ® PFA 345 is a medium melt flow rate fluoroplastic resin available in pellet form. Compared with Teflon ® PFA 340, it offers increased flex life and greater resistance to environmental stress-cracking (Teflon ® PFA 345 offers a typical MIT folding endurance of 50,000* compared to 15,000 in Teflon ® PFA 340). Table 1 shows the typical property data for Teflon ® PFA 345.

Teflon ® PFA 345 is used when traditional extrusion and molding processes are required for producing products with the superior properties of a fluoroplastic resin. Compared to other thermoplastics, the high melt strength and thermal stability of Teflon ® PFA 345 can be used to improve processing rates. Compared with other fluoroplastics, creep resistance at high service temperatures provides a superior balance and level of end-use properties. Teflon ® PFA 345 combines the processing ease of conventional thermoplastics with many properties similar to those of polytetrafluoroethylene.

Properly processed products made from neat Teflon® PFA 345 resin provide the superior properties characteristic of fluoroplastic resins: chemical inertness, exceptional dielectric properties, heat resistance, toughness and flexibility, low coefficient of friction, non-stick characteristics, negligible moisture absorption, low flammability, performance at temperature extremes, and excellent weather resistance.

In a flame situation, products of Teflon ® PFA 345 resist ignition and do not promote flame spread. When ignited by flame from other sources, their contribution of heat is very small and added at a slow rate with very little smoke.

Teflon ® PFA 345 meets the requirements of ASTM D3307, Type III