|

| 品牌 | 美国沙伯基础 |

| 货号 | 200 |

| 用途 | 配件 |

| 牌号 | IFX3420Z |

| 型号 | IFX3420Z |

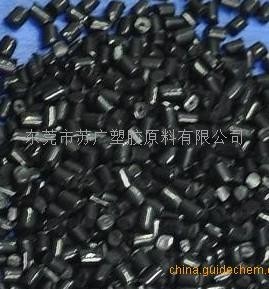

| 品名 | PC |

| 外形尺寸 | 100 |

| 厂家 | 美国沙伯基础 |

| 是否进口 | 是 |

安全眼镜LEXAN PC IFX2420Z IFX3420Z

Lexan* IFX3420Z is a medium viscosity, release containing, injection moldable, polycarbonate grade suitable for use in industry protective eye-ware welding applications. This grades meets the transmission and Haze/雾度requirements per ANSI 87.1 norm, Scale 3 when molded at 2.0 mm thickness.

相关色号:IFX3420Z-GN2D042T

| TYPICAL PROPERTIES (1) | |||

MECHANICAL机械性能 | Value | Unit | Standard |

Tensile Stress, yld, Type I, 50 mm/min / 抗拉强度,屈服,类型I,50 mm/min | 62 | MPa | ASTM D 638 |

Tensile Stress, brk, Type I, 50 mm/min / 抗拉强度, 断裂, 类型I, 50 mm/min | 65 | MPa | ASTM D 638 |

Tensile Strain, yld, Type I, 50 mm/min / 拉伸伸长, 屈服, 类型I, 50 mm/min | 7 | % | ASTM D 638 |

Tensile Strain, brk, Type I, 50 mm/min / 拉伸伸长,断裂,类型I, 50 mm/min | 110 | % | ASTM D 638 |

Tensile Modulus, 5 mm/min / 拉伸模量,5 mm/min | 2400 | MPa | ASTM D 638 |

Flexural Stress, yld, 1.3 mm/min, 50 mm span / 挠曲强度, 屈服, 1.3 mm/min, 50 mm 跨距 | 93 | MPa | ASTM D 790 |

Flexural Modulus, 1.3 mm/min, 50 mm span / 挠曲模量, 1.3 mm/min, 50 mm 跨距 | 2300 | MPa | ASTM D 790 |

Hardness, Rockwell M / 硬度, 洛氏 M | 70 | – | ASTM D 785 |

Hardness, Rockwell R / 硬度, 洛氏 R | 118 | – | ASTM D 785 |

Taber Abrasion, CS-17, 1 kg / 泰伯磨耗量, CS-17, 1 kg | 10 | mg/1000cy | ASTM D 1044 |

Tensile Stress, yield 50 mm/min / 抗张程度,屈服, 50 mm/min | 65 | MPa | ISO 527 |

Tensile Stress, break, 50 mm/min / 抗张程度,断裂,50mm/min | 70 | MPa | ISO 527 |

Tensile Strain, yield, 50 mm/min / 拉伸伸长,屈服,,50mm/min | 6 | % | ISO 527 |

Tensile Strain, break, 50 mm/min / 拉伸伸长,断裂,50mm/min | 120 | % | ISO 527 |

Tensile Modulus, 1 mm/min / 拉伸模量,1 mm/min | 2350 | MPa | ISO 527 |

Flexural Stress, yield, 2 mm/min / 弯曲强度,屈服,2 mm/min | 90 | MPa | ISO 178 |

Flexural Modulus, 2 mm/min / 弯曲模量,2 mm/min | 2250 | MPa | ISO 178 |

IMPACT | Value | Unit | Standard |

Izod Impact, unnotched, 23°C / 无缺口悬臂梁冲击 23°C | 3200 | J/m | ASTM D 4812 |

Izod Impact, notched, 23°C / 悬臂梁缺口冲击强度23°C | 850 | J/m | ASTM D 256 |

Izod IMPACT, notched, -30°C / 悬壁梁缺口冲击强度, -30°C | 135 | J/m | ASTM D 256 |

Falling Dart IMPACT / 落锤冲击 (D 3029), 23°C | 170 | J | ASTM D 3029 |

Instrumented Impact Total Energy, 23°C / 仪表控制抗冲击总能量,23°C | 65 | J | ASTM D 3763 |

Izod IMPACT, unnotched 80*10*3 +23°C | NB | kJ/m2 | ISO 180/1U |

Izod IMPACT, unnotched 80*10*3 -30°C | NB | kJ/m2 | ISO 180/1U |

Izod IMPACT, notched 80*10*3 +23°C / 悬壁梁缺口冲击强度, 80*10*3 +23°C | 70 | kJ/m2 | ISO 180/1A |

Izod IMPACT, notched 80*10*3 -30°C / 悬壁梁缺口冲击强度, 80*10*3 -30°C | 12 | kJ/m2 | ISO 180/1A |

Charpy 23°C, V-notch Edgew 80*10*3 sp=62mm / 简支梁缺口冲击强度,23°C,C80*10*3 sp=62mm | 73 | kJ/m2 | ISO 179/1eA |

Charpy -30°C, V-notch Edgew 80*10*3 sp=62mm / 简支梁缺口冲击强度,-30°C,C80*10*3 sp=62mm | 14 | kJ/m2 | ISO 179/1eA |

Charpy 23°C, Unnotch Edgew 80*10*3 sp=62mm | NB | kJ/m2 | ISO 179/1eU |

Charpy -30°C, Unnotch Edgew 80*10*3 sp=62mm | NB | kJ/m2 | ISO 179/1eU |

THERMAL | Value | Unit | Standard |

Vicat Softening Temp, Rate B/50 / 维卡软化温度 B级/50 | 154 | °C | ASTM D 1525 |

HDT, 0.45 MPa, 6.4 mm, unannealed / 热变形温度,0.45 MPa, 6.4 mm, 未退火 | 137 | °C | ASTM D 648 |

HDT, 1.82 MPa, 6.4 mm, unannealed / 热变形温度,1.82 MPa, 6.4 mm, 未退火 | 132 | °C | ASTM D 648 |

CTE, -40°C to 40°C, xflow / 线形膨胀系数,-40°C 到40°C,横向 | 7.E-05 | 1/°C | ASTM E 831 |

Specific Heat / 比热 | 1.25 | J/g-°C | ASTM C 351 |

Thermal Conductivity / 导热系数 | 0.19 | W/m-°C | ASTM C 177 |

CTE, -40°C to 40°C, flow / 线形膨胀系数,-40°C 到40°C,流动 | 7.E-05 | 1/°C | ISO 11359-2 |

CTE, -40°C to 40°C, xflow / 线形膨胀系数,-40°C 到40°C,横向 | 7.E-05 | 1/°C | ISO 11359-2 |

Vicat Softening Temp, Rate B/50 / 维卡软化温度 B级/50 | 141 | °C | ISO 306 |

Vicat Softening Temp, Rate B/120 / 维卡软化温度,B级/120 | 142 | °C | ISO 306 |

HDT/Af, 1.8 MPa Flatw 80*10*4 sp=64mm / 热变形温度,1.8 MPa, 未退火,80*10*4, 64.0 mm 跨距 | 123 | °C | ISO 75/Af |

PHYSICAL | Value | Unit | Standard |

Specific Gravity/比重 | 1.2 | – | ASTM D 792 |

Specific Volume/比容 | 0.83 | cm3/g | ASTM D 792 |

Density/密度 | 1.2 | g/cm3 | ASTM D 792 |

Water Absorption, 24 hours / 吸水率, 24小时 | 0.15 | % | ASTM D 570 |

Water Absorption, equilibrium, 23C / 吸水率,平衡,23C | 0.35 | % | ASTM D 570 |

Mold Shrinkage, flow, 3.2 mm / 模塑收缩量,流动,3.2 mm | 0.5 – 0.7 | % | SABIC Method |

Melt Flow Rate / 熔流率, 300°C/1.2 kgf / 熔流率,300°C/1.2 kgf | 12.5 | g/10 min | ASTM D 1238 |

Density/密度 | 1.2 | g/cm3 | ISO 1183 |

Water Absorption, (23°C/sat) / 吸水率, (23°C/sat) | 0.35 | % | ISO 62 |

Moisture Absorption (23°C / 50% RH) / 吸水率, 平衡,(23°C / 50% RH) | 0.15 | % | ISO 62 |

Melt Volume Rate, MVR at 300°C/1.2 kg | 12 | cm3/10 min | ISO 1133 |

OPTICAL | Value | Unit | Standard |

Light Transmission/透光率 | 13.3 | % | ASTM D 1003 |

Haze/雾度 | 2.2 | % | ASTM D 1003 |

Refractive Index /折射指数 | 1.586 | – | ASTM D 542 |

Source GMD, last updated:09/30/2008 |

Processing |

| Parameter | ||

Injection Molding | Value | Unit |

Drying Temperature / 干燥温度 | 120 | °C |

Drying Time / 干燥时间 | 3 – 4 | hrs |

Drying Time (Cumulative) / 干燥时间(累积的) | 48 | hrs |

Maximum Moisture Content / *含湿量 | 0.02 | % |

Melt Temperature / 熔体温度 | 295 – 315 | °C |

Nozzle Temperature / 注嘴温度 | 290 – 310 | °C |

Front – Zone 3 Temperature / 前区3温度 | 295 – 315 | °C |

Middle – Zone 2 Temperature / 中区2温度 | 280 – 305 | °C |

Rear – Zone 1 Temperature / 后区1温度 | 270 – 295 | °C |

Mold Temperature / 模具温度 | 70 – 95 | °C |

Back Pressure / 背压 | 0.3 – 0.7 | MPa |

Screw Speed / 螺杆速度 | 40 – 70 | rpm |

Shot to Cylinder Size / 每次注射量占料筒熔胶总量的百分比 | 40 – 60 | % |

Vent Depth / 排气孔深度 | 0.025 – 0.076 | mm |