|

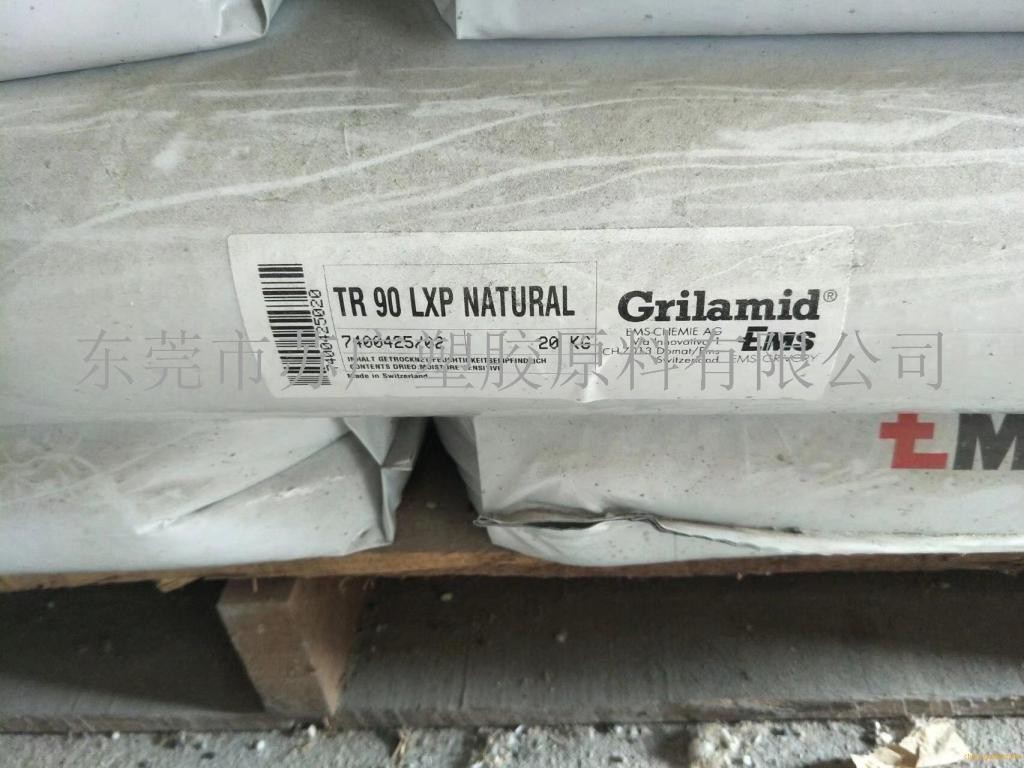

| 品牌 | Grilamid |

| 货号 | Grilamid |

| 用途 | 配件 |

| 牌号 | TR 90 LXS |

| 型号 | Grilamid |

| 品名 | PA MACM12 PA12 Grilamid TR 90 LXS TR90LXS |

| 包装规格 | 25kg |

| 外形尺寸 | 25kg |

| 厂家 | Grilamid |

| 是否进口 | 是 |

PA MACM12 PA12 Grilamid TR 90 LXS TR90LXS

Information provided by EMS Grivory

| 物理性能 | 额定值 (公制) | 额定值 (英制) | 测试方法 |

|---|---|---|---|

| 密度 | 1.00 g/cc | 0.0361 lb/in3 | ISO 1183 |

| 吸水率 | 3.0 % | 3.0 % | ISO 62 |

| 水分吸收 | 1.50 % | 1.50 % | ISO 62 |

| 线性成型收缩率,Flow | 0.0050 cm/cm | 0.0050 in/in | ISO 294-4, 2577 |

| 线性成型收缩率,横向 | 0.0060 cm/cm | 0.0060 in/in | ISO 294-4, 2577 |

| 机械性能 | 额定值 (公制) | 额定值 (英制) | 测试方法 |

|---|---|---|---|

| 球压硬度 | 85.0 MPa | 12300 psi | conditioned; ISO 2039-1 |

| 抗张强度(断裂) | 40.0 MPa | 5800 psi | conditioned; ISO 527-1/-2 |

| 抗张强度(屈服) | 60.0 MPa | 8700 psi | conditioned; ISO 527-1/-2 |

| 伸长率 (断裂) | >= 50 % | >= 50 % | conditioned; ISO 527-1/-2 |

| 屈服伸长率 | 6.0 % | 6.0 % | conditioned; ISO 527-1/-2 |

| 拉伸模量 | 1.50 GPa | 218 ksi | conditioned; ISO 527-1/-2 |

| 简支梁无缺口冲击强度 | NB | NB | conditioned; ISO 179/1eU |

| NB @Temperature 30.0 °C | NB @Temperature 86.0 °F | conditioned; ISO 179/1eU | |

| 简支梁缺口冲击强度 | 0.900 J/cm2 | 4.28 ft-lb/in2 | conditioned; ISO 179/1eA |

| 1.20 J/cm2 @Temperature 30.0 °C | 5.71 ft-lb/in2 @Temperature 86.0 °F | conditioned; ISO 179/1eU |

| 电气性能 | 额定值 (公制) | 额定值 (英制) | 测试方法 |

|---|---|---|---|

| 体积电阻率 | 1.00e+13 ohm-cm | 1.00e+13 ohm-cm | conditioned; IEC 60093 |

| 表面电阻 | 1.00e+12 ohm | 1.00e+12 ohm | IEC 60093 |

| 介电强度 | 35.0 kV/mm | 889 kV/in | conditioned; IEC 60243-1 |

| 相比耐漏电起痕指数(CTI) | 600 V | 600 V | conditioned; IEC 60112 |

| 热性能 | 额定值 (公制) | 额定值 (英制) | 测试方法 |

|---|---|---|---|

| 线形热膨胀系数 - 流动 | 90.0 μm/m-°C | 50.0 μin/in-°F | ISO 11359-1/-2 |

| 线性热膨胀系数,横向流动 | 90.0 μm/m-°C | 50.0 μin/in-°F | ISO 11359-1/-2 |

| 工作温度, Air | 80.0 °C | 176 °F | long term; EMS |

| 95.0 °C | 203 °F | short term; EMS | |

| Transformation Temperature, Tg | 125 °C | 257 °F | 10°C/min; ISO 11357-1/-2 |

| 载荷下热变形温度(0.46 MPa) | 100 °C | 212 °F | ISO 75-1/-2 |

| 载荷下热变形温度(1.8 MPa) | 80.0 °C | 176 °F | ISO 75-1/-2 |

| 可燃性(UL94) | HB | HB | IEC 60695-11-10 |

| 光学性能 | 额定值 (公制) | 额定值 (英制) | 测试方法 |

|---|---|---|---|

| Transmission, Visible | 90 % | 90 % | transparent; thickness not quantified |

| 材料描述 | 测试方法 | |

|---|---|---|

| 汽车 | Automotive electr. and electronics, lighting | |

| Cooling and climate control | ||

| Fuel systems | ||

| Interior | ||

| Powertrain and Chassis | ||

| 电器及电子产品 | Connectors | |

| Electrical appliances | ||

| Electrical equipment | ||

| Energy distribution | ||

| Lighting | ||

| Mobile phones and other portable devices | ||

| Food contact | EU Requirements | |

| FDA | ||

| 形式 | Granules | |

| 工业和消费品 | Housewares | |

| Hydraulics & Pneumatics | ||

| Mechanical Engineering | ||

| Medical devices | ||

| Power transmission | ||

| Sanitary, water and gas supply | ||

| Sports & Leisure | ||

| Tools & Accessories | ||

| Optics | Optical components | |

| Safety glasses | ||

| Spectacle frames | ||

| Sunglasses | ||

| 加工 | Injection Molding | |

| 产品属性 | Improved alcohol resistance | |

| Improved flowability and demoulding | ||

| 特殊特性 | Transparent |